Priorities

Problem:

Note: The animations could only work if the "Zoom" of the browser is equal to 100%. If you need to adjust, go to settings of the browser.

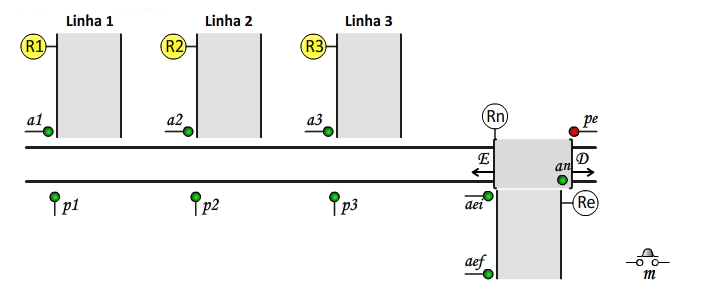

A car transports products from three independent conveyors to an evacuation conveyor:

The system has several sensors: ai – detects the presence of a part in line 1, with i=1,2,3; an – detects the presence of a part in the transportation car; aei – detects the presence of a workpiece at the beginning of the evacuation conveyor; aef – detects the presence of a piece on the end of the evacuation conveyor; pi – limit sensor, indicates the positioning of the transportation car in the end of line I, with i=1,2,3; pe – indicates the positioning of the car at the beginning of the evacuation conveyor. The actuators are the following: E – moves the car to the left; D – moves the car to the right; Ri – motor of conveyor i, with i = 1,2,3 (lines), n (car), e (evacuation); The transportation car capacity is one part and its initial position is near the evacuation conveyor. Logical controllers are implemented for the following cases with Grafcets:

Example 5.1:

- The proposed problem is solved by using partial grafcets

- In the transport car Grafcet the selection of sequences is defined by using priorities.

- It is defined a certain order to collect objects from the respective lines, in the case of more than one is line busy.

- It is possible for the user to change the priorities by using the menu “Priority”.

- The sequences priorities are defined from the left to the right. This can be observed by the changing of the transition conditions at the beginning of each sequence.

Note: There are several buttons, bellow the button/switch, m, which allows to control the pace of the animation. Thus, for a better understanding of the Grafcet evolution it is possible to pause the animation and go through the evolution frame by frame

the animation and go through the evolution frame by frame

. At any moment the normal pace can be resumed

. At any moment the normal pace can be resumed

. Button

. Button

allows to re-start the animation.

allows to re-start the animation.

Initially the car and all the conveyors are empty. When line 1 is operating, the motor it’s stopped when a part is detected by the respective position sensor, a1, remaining stopped until the transportation car arrives and the part is removed to be evacuated. The same applies to lines 2 and 3. By pressing button m, the car will transport a part. In the case of none part to be transported the cars waits. The priority to serve the lines is defined from the left to the right (initially, line 1 with the highest priority and line 3 with the lowest priority).

Example 5.2:

- The problem is solved with partial grafcets.

- The selection of sequences is defined by using priorities.

- The lines priorities is alternated, and in this way the lines do not hold the same priority always.

- The change performed in the functions associated with the receptivity’s, in the sequence selection, together with Grafcet controlling the priorities, allows to perform the change in priorities for the lines.

- Check how to write logical functions to the receptivity’s, with higher complexity, which allow to modify the model, to implement the controller in this case.

Note: There are several buttons, bellow the button/switch, m, which allows to control the pace of the animation. Thus, for a better understanding of the Grafcet evolution it is possible to pause the animation and go through the evolution frame by frame

the animation and go through the evolution frame by frame

. At any moment the normal pace can be resumed

. At any moment the normal pace can be resumed

. Button

. Button

allows to re-start the animation.

allows to re-start the animation.

For the same problem as the one proposed in 5.1, the aim is to implement priorities for the lines, but alternatively. A line has priority over the other two just once, then the priority is given to the following line. Initially the priority is given to line 1, followed by line 2 and finally line 3, returning to line 1, and so on.